After undergoing an extensive qualification process, our 8.5K+ certified vendors are organized into an empirical quality hierarchy that prioritizes procurement from the lowest-risk suppliers. We continuously monitor their performance throughout the industry, immediately restricting suppliers with reported issues.

Our engineers and quality control inspectors maintain the same testing criteria in all our facilities, establishing consistent, orderly operations.

We can adapt our AQL and AS6081 sampling plans to accommodate specific parts, quantities, and customer requirements.

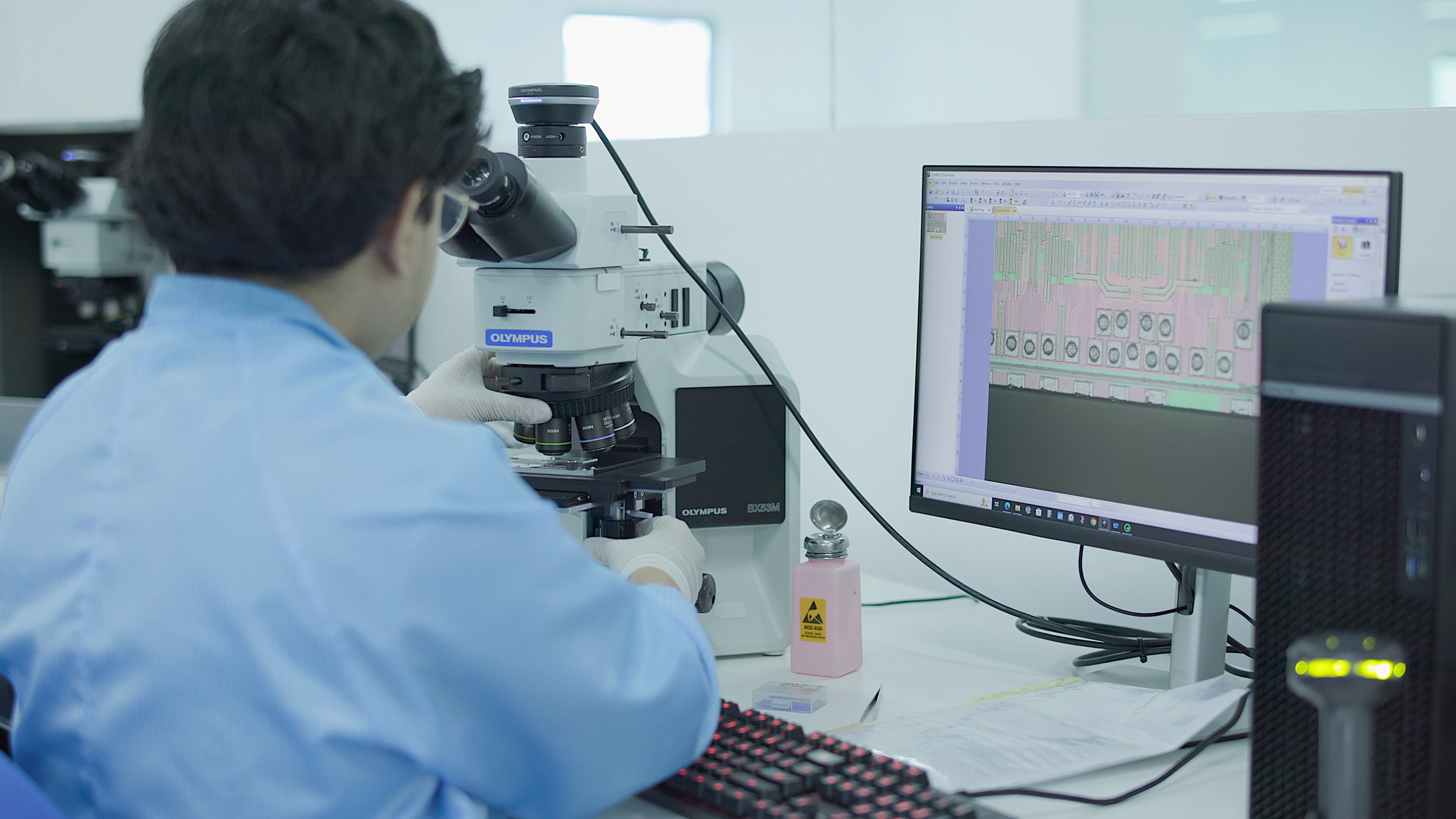

All electronic components are inspected under four levels of magnification, including 2000x.

We cross-reference results with our Device Information Exchange (DIE) Database, a deep library of historical data from past tests and documentation from the ERAI and IHS.

Fusion Worldwide provides every customer with an exhaustive inspection report after each quality testing process.

Fusion's Process

Combining the industry’s most advanced technology with insights from our in-house database

We count and organize your electronic components by part and serial number, taking detailed photographs of each

After determining the quantity and country of origin of your parts, we assign them unique lot and date codes

We carry out a second review of your parts to confirm exact quantities and specifications

Our on-floor quality assurance personnel scans your electronic components into our proprietary database

Our IDEA-ICE-3000 certified inspectors perform internal and external visual inspections of all electronic components

We authenticate the integrity of your parts through lead inspection, scrape testing, acetone testing, and marking permanency testing

Our experienced engineers conduct more advanced tests using X-rays, X-ray Fluorescence (XRF), and high-end microscopes, including KEYENCE equipment

We employ heated and chemical decapsulation testing to verify the authenticity of the parts, along with solderability testing to ensure the component's leads or terminations can be effectively soldered.

We further analyze your parts’ electrical performance and quality with custom tests in our secure labs

Our engineering team uses curve tracers, functional testing, or Inductance, Capacitance, and Resistance (LCR) measurements to assess active and passive component properties

Excellence Is Our Standard

Our DIE Database houses information on past inspections, photographs of every electronic component, and the latest industry data from the ERAI, IHS, and Silicon Expert. This gives our inspectors a reliable archive to reference when examining and testing parts.

Advancing as Testing Advances

Fusion Worldwide’s award-winning, proprietary quality management system, Scout RMS™, is a key driver in our quality control process. From receiving and testing to packaging and shipping, our system features improve operations.

Customer Requirements: Scout RMS™ prioritizes our customers’ needs and specifications.

Process Documentation: Quality control managers are required to log every inspection into our system.

Component Database: Scout RMS™ stores historical data, industry information, digital photographs, and more.

Process Checkpoints: Security lockouts are placed at critical inspection points to confirm no errors have been made.

Equipment Calibration: Our QMS sends automatic notifications when equipment nears its scheduled maintenance.

Inventory Management: Scout RMS™ helps us monitor all inventory to guarantee parts never co-mingle.

Logistics Management: Our system catalogs each part and tracks its progress from receiving to shipping.

Non-Compliance Documentation: Scout RMS™ records all issues related to non-conforming products and the actions taken to resolve them.

General Inquiry